Fabien Mons-Quendo, Jean-François Blachot, Jean-Philippe Poirot-Crouvezier, Christophe Carral, Patrice Mele, Sébastien Kawka, Stress modelling from land/channel to full PEMFC stack using homogenization method, International Journal of Hydrogen Energy, Volume 198, 2026, 152592, ISSN 0360-3199

Proton exchange membrane fuel cells (PEMFCs) consist of stacked cells compressed between two clamping plates. The performance and durability of the PEMFC components within the stack depend on the nominal pressure applied by these plates.

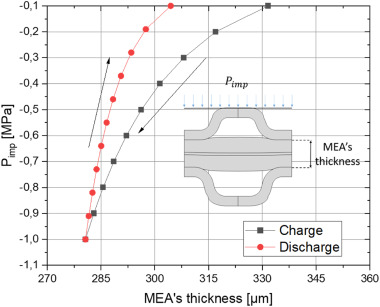

Insufficient pressure may result in poor electrical contact between the cells and potential leakage, whereas excessive pressure can lead to over-compression of the membrane electrode assembly, thereby impairing its transport properties.

The nominal pressure can be set through experimentation or by using simple mechanical models at a land/channel scale smaller than 1 mm. However, these methods do not account for the stress heterogeneities within the hundreds of cells in the stack, which measures several decimeters in size, nor do they consider the stress variations during operation or clamping.

Performing a full 3D calculation of the entire stack to determine the detailed stress distribution in each component requires an enormous number of finite elements, rendering the calculation prohibitively costly in terms of both time and resources. In this study, we present an original homogenised mechanical model of the stack. This model facilitates the calculation of the stress distribution within each component of the entire stack. Applied to a stack designed with metallic bipolar plates, the model captures the heterogeneous deformation levels of the gas diffusion layers (GDLs), which vary from approximately 30 % at the periphery of the stack to around 15 % at its centre.

It shows also that an inappropriate choice of sealing properties can lead to a 17 % decrease in the nominal pressure at the center of the stack after the clamping process. However, the primary outcome of this study is the development and application of a homogenised model that significantly reduces computational costs. Specifically, the simulation of the clamping process required 40 min on a standard workstation.

This advancement facilitates the optimization of the balance of plant design.